5 Common Mistakes Sign Fabricators Make

Signage plays a vital role in everyday life, from helping us navigate where we need to go to providing the information we need. However, as sign fabricators, we know the process of sign making can be quite complex, involving precision, accuracy, and attention to detail.

Although no sign fabricator is perfect, it is easy to avoid mistakes when you can identify the inefficiency and know what exactly needs to be done to improve. To help you enhance your sign manufacturing process, we have uncovered the 5 most common mistakes made within the sign industry.

1. Non-Compliance with the ADA

The Americans with Disabilities Act (ADA) requires business establishments to provide accommodations for those who are disabled. Ensuring your signage complies with the ADA is a matter of paying attention to detail. Font, braille placement, mounting height, and pictogram placement are the most common areas where signs fail to meet compliance requirements.

- Font: All characters must be in uppercase, in Sans Serif, and ⅝ inch minimum and 2 inches maximum.

- Braille Placement: Braille allows visually impaired individuals to read and write. In the United States, ADA-Compliant signage must use Grade II braille.

- Mounting Height: Mount your signage at least 48 inches above the floor or at most 60 inches above the floor.

- Pictogram Placement: Make sure you have an area of 6-inches for each pictogram. Although there are no specifications to the actual height of the pictogram, 4.5-inches is recommended.

Nova Polymers’ Workflow Manager software has the tools to combat these issues as it can create ADA-compliant signage easily and efficiently. The software automatically ensures braille placement, offers compliant fonts, and makes sure your text complies with federal standards.

2. Not Getting a Proof Approved Ahead of Time

Proofs are items or files that are sent to the client to give them a vision of how the finished signage product will look. A proof can be a superimposed image of the signage on a building or wall as it appears in real life. Keep in mind that a proof does not have to be a completed sign, it can be sent via image rendering or in printout form.

By giving the client a sample proof of the finished sign, you can correct mistakes right away. When proofs are sent out to clients, they have a chance to double-check whether spelling, braille, text size, pictograms, and contact details are correct. Clients can also use this proof to get third-party opinions of the signage by showing the proof to their team for feedback. This is important because it allows clients to get an idea of the finished product and make necessary revisions before the actual sign is made. Getting signage proofs approved ahead of time allows you to save money and resources in the long run and will help you avoid problems and customer complaints.

3. Wasting Too Many Materials

3. Wasting Too Many Materials

It’s very easy for sign fabricators to overlook the possibility of using too many materials due to human error and miscalculations. For example, there are many cases in which the printed text and braille only cover a small portion. Scraps often happen in the cutting process, and due to the shapes of most signages, they cannot be repurposed. As a result, the unused sections of the sheet are disposed of. To keep this from repeatedly happening, it is important to train your employees to go out of their way to get the most out of the materials. Additionally, it is a good business decision to incorporate software that minimizes the risk of human error and material waste.

4. Making Too Few or Too Many Signs

As the old saying goes, “too much or too little of anything is bad for you.” In the sign industry, it is not uncommon for sign fabricators to make too many or too few signs. Sometimes, fabricators miscalculate and make too many signs for one specific project. This results in an excess of signage that is not needed and an unnecessary amount of materials wasted. At the same time, making too few signs can be harmful to your business as it can lead to missed deadlines.

The creation of too much or too little signage usually occurs due to human error and miscommunication. It is essential to double or even triple check orders so that errors do not arise from misreading the quantity ordered by the client. It also does not hurt to reconfirm with the client about the number of signs they ordered from you.

Another way to combat the issue is to have a black and white proof created for every film file. This proof can be small to not waste material. When creating signage, each film that correlates to the laser proof can be crossed off, allowing you to have the same amount of film as black and white lasers. Although it takes time to make copies of output files, it is worth it in the long run because you will be able to ship on time and not waste any materials.

5. Other Common Photopolymer Inefficiencies

Aside from the topics mentioned above, there are several other inefficiencies sign manufacturers must be aware of when producing photopolymer signage:

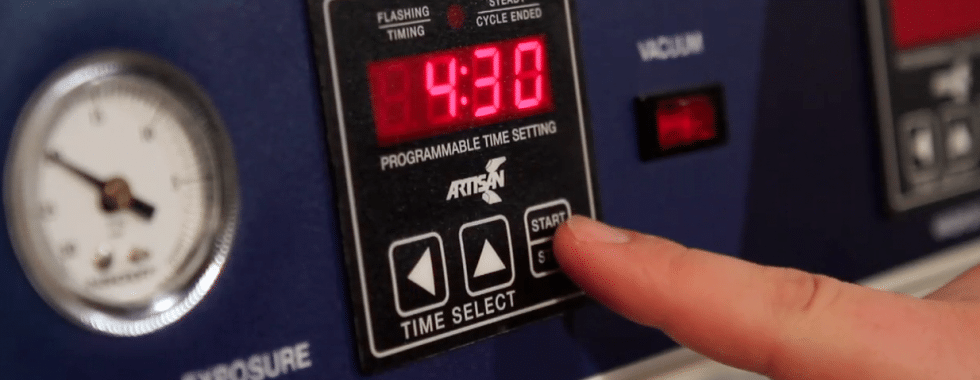

- Old Bulbs: Make sure that your bulbs are up-to-date so that exposure times are good. Bulbs need to be changed every few years, depending on how often they are used. Keep in mind that these bulbs must not be more than 2 to 3 years old. Bulbs that are used every day must be changed once a year since they have a higher risk of burning out.

- Stouffer Scale: Using the Stouffer Scale regularly ensures that your bulbs are working properly. For PT Materials, the Stouffer Scale should read 15-16. For Exterior Materials, the Stouffer Scale should read 12-13.

- Washout Time: Your washout time should not be too long or excessive. Five minutes is enough time to wash all your products. If your washout time exceeds five minutes, there might be something wrong with your brush. Make sure that your brush is adjusted properly before using and washing.

- Drying Time: Do not skip the drying process. The drying time allows the photopolymer to bond well to the backer material. Signage must be dried for at least 15 minutes in the dryer.

Key Takeaways

As you become more aware of the common mistakes made by sign fabricators, it is a good time to reevaluate your own workflow processes and make the necessary improvements to become more productive and efficient. Addressing all these common mistakes by training your team will help you become more successful and achieve increased profits and revenue in the long run.

Nova Polymers can help you identify and solve production and workflow inefficiencies so that your signage business can flourish. For more information on our services, contact us today.