How To Improve Your Photopolymer Quality and Cycle Times

Better Vacuum Equals Better Quality

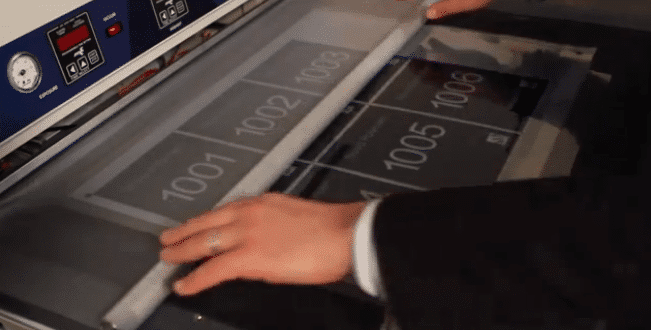

As part of our Did You Know summer camapign, we thought it would be beneficial to talk about the importance of the vacuum processes when producing photopolymer signs. The vinyl cover sheet or “krene” is one of the most important elements in creating a good sign.

Ensuring proper exposure is the key to successfully producing a proper photopolymer signs and maintaining consistent cycle times. Before you start worrying about the correct amount of light (measured with a 21 Step Stouffer Scale), you need to make sure that you have intimate contact between the film negative and the photopolymer sheet.

The vinyl cover sheet helps draw down the vacuum and makes sure there is no air trapped under the negative. Over time the vinyl cover sheet wears out and needs to be replaced. A new vinyl cover sheet also decreases exposure times which increases productivity.

A New Kind of Cover Sheet

We’ve recently made some change to the vinyl cover sheet that allow more UV to pass through and decrease the exposure time. This will increase your overall productivity and reduce cycle times. Since the washout is approx. 5 minutes, the goal is to keep the exposure time under that so there is no bottleneck in the process.

Changing the vinyl cover sheet is part of the maintenance procedures and should be done on a monthly basis.

Vinyl Cover Sheet Info

Contact us to get pricing and more information on our vinyl cover sheets.