Why You Need To Change Your Bulbs

Improve Cycle Times and Quality

Exposure to UV light is what creates the photopolymer elements of a sign. The photopolymer that comes in contact with the UV light hardens allowing the unexposed polymer to wash away in plain water during the washout process. The amount of UV light shapes the shoulders of Braille dots to make them ADA complaint.

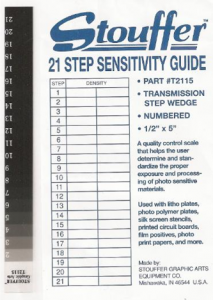

The intensity of the bulbs decrease over time which means that the actual exposure time increases to maintenance a solid 16 on the Stouffer Scale. The optimal life span of a set of bulbs is 300 hours which mean they need to be replaced annually.

There are 16 bulbs in the main exposure draw in our Orbital X processor and 14 post exposure lamps. Both sets should be replaced at the same time. If you are using a different photopolymer process you still need to replace the bulbs with the same frequency.

There are 16 bulbs in the main exposure draw in our Orbital X processor and 14 post exposure lamps. Both sets should be replaced at the same time. If you are using a different photopolymer process you still need to replace the bulbs with the same frequency.

The 21 Step Stouffer Scale measures the amount of light so you know when to increase the exposure time to maintain the correct shoulders on your Braille dots. Learn more about to properly create ADA compliant Braille.

If you change your bulbs at the recommend time and continually replace your vinyl cover sheet, not only will your quality be consistent but you will maintain proper cycle times and be able to procure 9-12 cycles per hour in you photopolymer processor.

Request Pricing on New Exposure Bulbs

Fill out the form below to review pricing and information on new exposure bulbs.