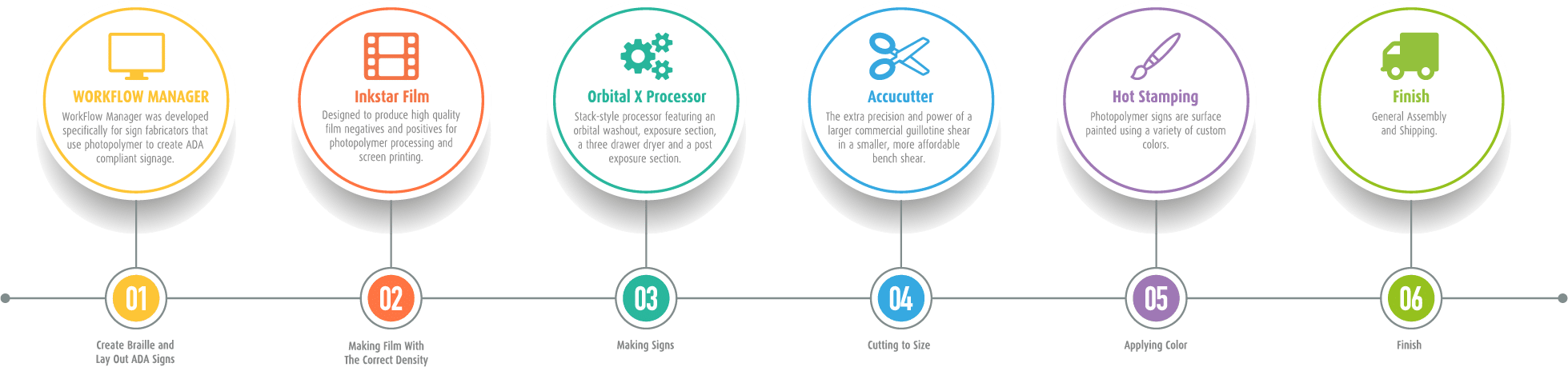

Having an ideal workflow is the key to any successful business venture related to signage or manufacturing in general. There are a few key components needed to successfully produce Novacryl photopolymer signage in-house. We’ve created a great infographic to demonstrate a typical workflow environment.

How Photopolymer Signs Are Processed

- Artwork is created using our WorkFlow Manager design and Braille translation software

- Film used to expose the photopolymer is generated with the InkStar Film Solution which prints high-density negatives and positives

- Processing the actual Novacryl® photopolymer is done with the All-In-One Orbital X Photopolymer Processor

- Once processed the photopolymer gets cut with either a CNC router or with the AccuCutter Finishing Shear

- Applying color to the photopolymer sign panel is done by spraying Matthews Acrylic Polyurethane Paint to either the surface or second surface of the Novacryl® sign panel

- Tipping the raised characters are done with the Kobo TC-851 Hot Stamp unit

- The last step is assembly of all the sign components, packaging, and shipping

It’s just that easy – and we’ve done the math. Our signage process is profitable after just 1500 signs.

Watch our Novacryl® Processing Video to see a live demo of how a photopolymer sign is made.

Request more information on Nova Polymers and ADA/Visually Impaired signage

Please complete the form below to identify your specific interests.