Seizing the Workflow Advantage for ADA Signage

Plenty of sign fabricators sub-contract ADA-compliant braille signage production because they think it is too complicated and are reluctant to climb the learning curve that goes with offering ADA-compliant signs. If you are doing this, you’re leaving a lot of money on the table.

Ensuring the signs you produce satisfy ADA requirements is largely a matter of paying attention to a few important details. This may seem intimidating but is made easier by using equipment and software developed with the needs of sign makers in mind. You still need to familiarize yourself with federal, state and local regulations, but actual sign production can be a straightforward process that expands your company’s capabilities and can put larger numbers on your bottom line.

Software to the rescue

Renown for its ease of use, Workflow Manager from Nova Polymers is proprietary software developed to demystify and simplify the creation of ADA-compliant signage and help sign fabricators streamline production and increase profitability. Workflow Manager 2.0 is 100 percent ADA compliant in the U.S.; AODA compliant in Canada; and meets the equivalent requirements in Australia.

WorkFlow Manager 2.0 also reliably produces Grade II braille, the most common and popular form, which incorporates contractions of certain words and makes the language more efficient. The software is designed to work with Unified English Braille (UEB), a standard developed by English-speaking countries for unifyng the braille symbols used in literary, mathematics and computing contexts. In addition, Workflow Manager 2.0 creates the negatives needed for photopolymer processing faster and more easily, ensures accurate size and spacing of the correct sans serif font characters, supports proofing of the associated braille “cells”, and quickly creates proofs for approval.

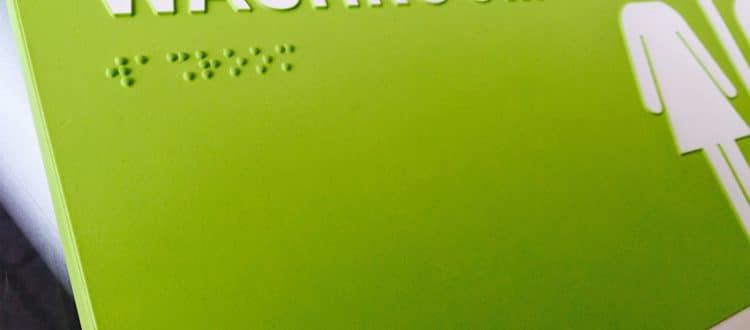

Bread and butter applications

A common application for ADA signage is signs identifying rooms in an office building, such as meeting spaces, restrooms, stairways, and offices. In many instances, such signs are of similar size, varying only by the identifying information. Using Workflow Manager 2.0 all the information for each room can be placed in a single Microsoft Excel file. After a designer creates a template for the signs, Workflow Manager populates the templates with the information from the Excel worksheet. Workflow Manager then produces a negative with both standard text and braille characters that can be used to create a plate in a device such as Nova Polymers’ Orbital Photopolymer Processor. This significantly shortens the time required to produce signs by circumventing the need to design a sign in a program such as Illustrator, proof the file and export it for production. As a result, Workflow Manager lets your team produce more signs faster, and with greater accuracy and reliability.

A common application for ADA signage is signs identifying rooms in an office building, such as meeting spaces, restrooms, stairways, and offices. In many instances, such signs are of similar size, varying only by the identifying information. Using Workflow Manager 2.0 all the information for each room can be placed in a single Microsoft Excel file. After a designer creates a template for the signs, Workflow Manager populates the templates with the information from the Excel worksheet. Workflow Manager then produces a negative with both standard text and braille characters that can be used to create a plate in a device such as Nova Polymers’ Orbital Photopolymer Processor. This significantly shortens the time required to produce signs by circumventing the need to design a sign in a program such as Illustrator, proof the file and export it for production. As a result, Workflow Manager lets your team produce more signs faster, and with greater accuracy and reliability.

Adding services, increasing control

More importantly, using Workflow Manager in conjunction with materials from Nova Polymers and the Orbital Photopolymer Processor, sign fabricators can easily and affordably add ADA signage production to their standard line of services, eliminating the need to subcontract this growing and lucrative line of business.

John Keebler, Director of Engineering at L&H Companies, an award-winning sign fabricator in Reading, Pennsylvania, says L&H began using Workflow Manager when the company decided to bring ADA signage production in-house rather than using a subcontractor.

“We were already doing all of the exterior and most of the interior signage for our projects so it made sense to offer ADA signage as well. We like to manufacture as much as we can in-house. It is more efficient for our customers and gives us better control over an entire project“.

According to Mr. Keebler, a key advantage to Workflow Manager 2.0 is the speed of translating the Excel data to a negative that can be used to make a plate directly from the software. “This provides a faster turnaround, higher quality, better process control, and requires fewer people. On top of that, the photopolymer sign we get is basically a single piece so it is also more durable, and because of the way Workflow Manager works, we know it will be ADA compliant“.

Mr. Keebler says the advantages to using photopolymer technology and Workflow Manager show up quickly in the manufacturing process, where creating negatives that can immediately be used to produce plates is about 25 percent faster. “With Workflow Manager 2.0 we are creating the numbers, letters and braille for a sign all at once, and we get a negative that’s ready for the processor. We see fewer errors and have higher reliability“.

Reach out to Nova Polymers to learn how Workflow Manager 2.0 can help simplify ADA signage production in your business while increasing throughput, accuracy and efficiency.