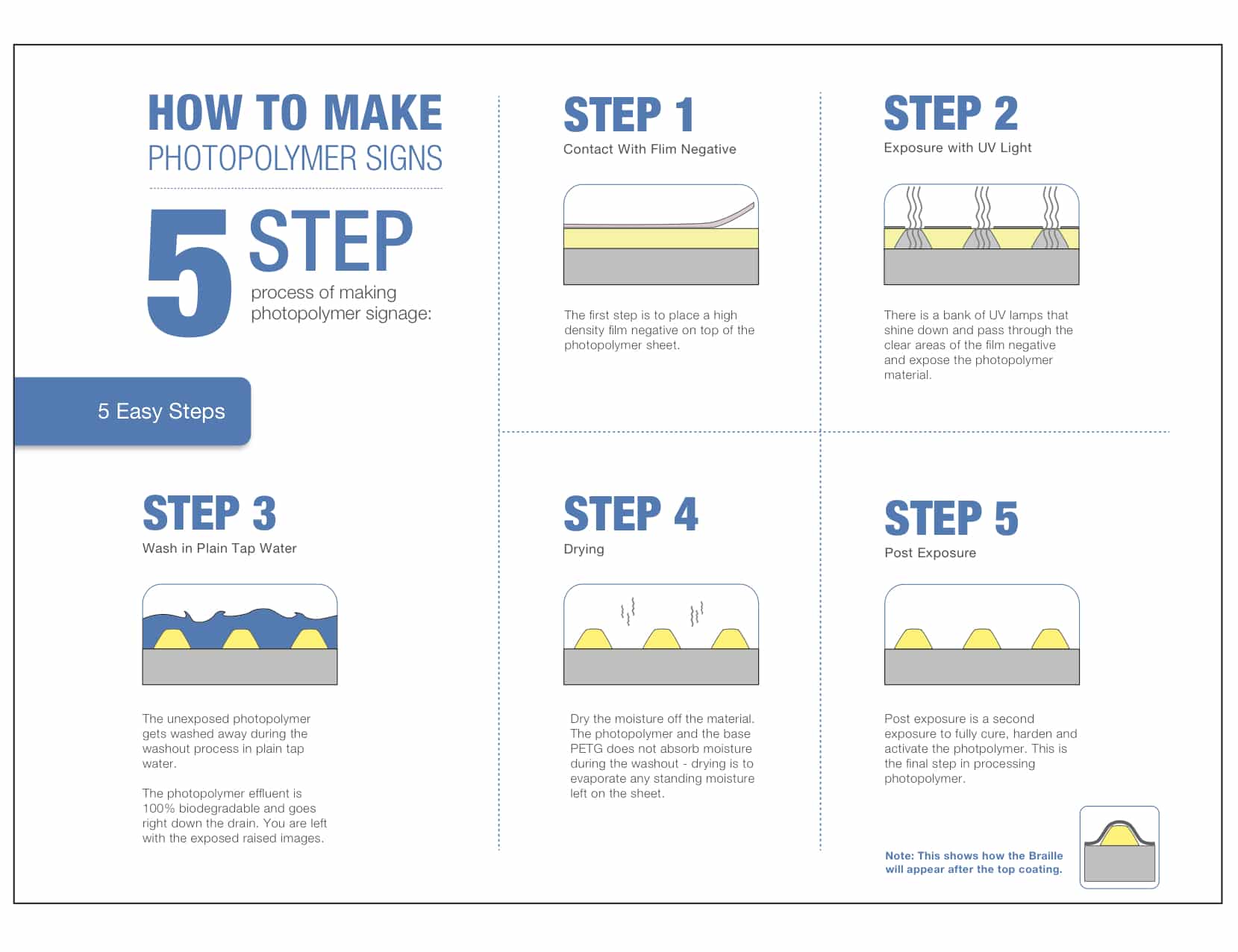

Understanding Photopolymer Equipment and the 5 Step Process for Making ADA Signs

Business is competitive today and we are all looking for an edge – more control, increased profits, and enhanced quality. These three reasons are why photopolymer ADA sign production has dominated the market for the last two decades and stays one of the most efficient and profitable ways to create opportunities, especially if you sell 1,000 or more ADA signs annually.

There are five essential pieces of equipment needed to fabricate photopolymer ADA signs. The process is geared for volume and quality.

Workflow Manager – Creating Braille and Laying Out an ADA Sign

Sign companies are expected to be the experts when it comes to ADA sign codes. There are four main areas of focus related the design of an ADA sign:

Sign companies are expected to be the experts when it comes to ADA sign codes. There are four main areas of focus related the design of an ADA sign:

- Fonts

- Character size

- Kerning

- Braille

(Download a PDF summarizing the ADA sign guidelines for the 4 main areas)

Workflow Manager (WM) follows all the current ADA guidelines. The software will not allow you to use a non-compliant font, or make the test larger than 2”. Kerning is automatic so that the closest point on any two character is ⅛” apart. When using WM you will be sure to create compliant signage.

WM software also allows you to import variable data from a room schedule and auto populate each sign with the given data. Braille is automatically generated with the imported data saving hours of time during the design and layout phase.

>> Learn More About Workflow Manager

InkStar Film – Making Film with the Correct Density

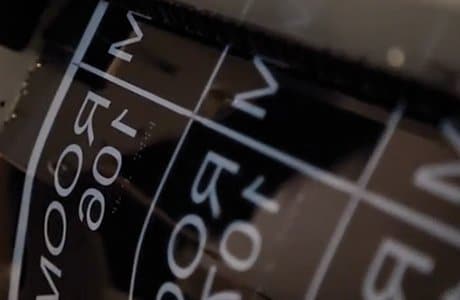

Once a file is created using WM, the next step is to generate a film negative. We use an Epson Inkjet printer configured with our DyeStar Ink. The DyeStar Ink has a UV inhibitor that’s been designed to block the UV light during the exposure and processing of the photopolymer.

Once a file is created using WM, the next step is to generate a film negative. We use an Epson Inkjet printer configured with our DyeStar Ink. The DyeStar Ink has a UV inhibitor that’s been designed to block the UV light during the exposure and processing of the photopolymer.

The printer is not modified. Instead, we use RIP software that controls the amount of ink flow and density.

The width of the Epson printer is 24”. The size of the photopolymer sheet is 19” x 25” so the typical file size create is approx. 18.5” x 23.5”. If you need to go longer than 24” you can orient the film so that the 19” prints across the width of the film and the 25” prints the length of the film.

>> Learn More About Inkstar Film Solutions

Orbital X Photopolymer Process – Making Signs

Once you have your film, the next step is processing the photopolymer sheet in the Orbital X Photopolymer Processor (OrbX). The OrbX is a stacked unit that includes a main exposure drawer with vacuum, a washout tank, 3 dryer drawers, and a post exposure drawer.

Once you have your film, the next step is processing the photopolymer sheet in the Orbital X Photopolymer Processor (OrbX). The OrbX is a stacked unit that includes a main exposure drawer with vacuum, a washout tank, 3 dryer drawers, and a post exposure drawer.

The film is placed on the photopolymer sheet in the exposure drawer with the vacuum. UV light exposure the areas of the photopolymer that are clear on the film negative. This process hardens everything that is exposed to the light and will remain raised after the washout.

Once exposed, the sheets is washed with plain tap water in the wash out section of the OrbX. The areas of the photopolymer that were not exposed to light will wash away and dissolve in the water leaving the raised (exposed) areas behind. This is process lets you easily create raised text, characters, pictograms, Braille, borders, etc.

After the sheet is washed, it is placed in the dryer for approx. 10-20 min to dry off any standing moisture. Note that the photopolymer does not absorb moisture nor does the PETG base. PETG, otherwise known as Polyethylene Terephthalate, is a clear amorphous thermoplastic resin of the polyester family that can be injection molded or sheet extruded.

The final step is to expose the entire sheet a second time without using the film negative to further harden the photopolymer.

>> Learn More About the Orbital X Photopolymer Processor

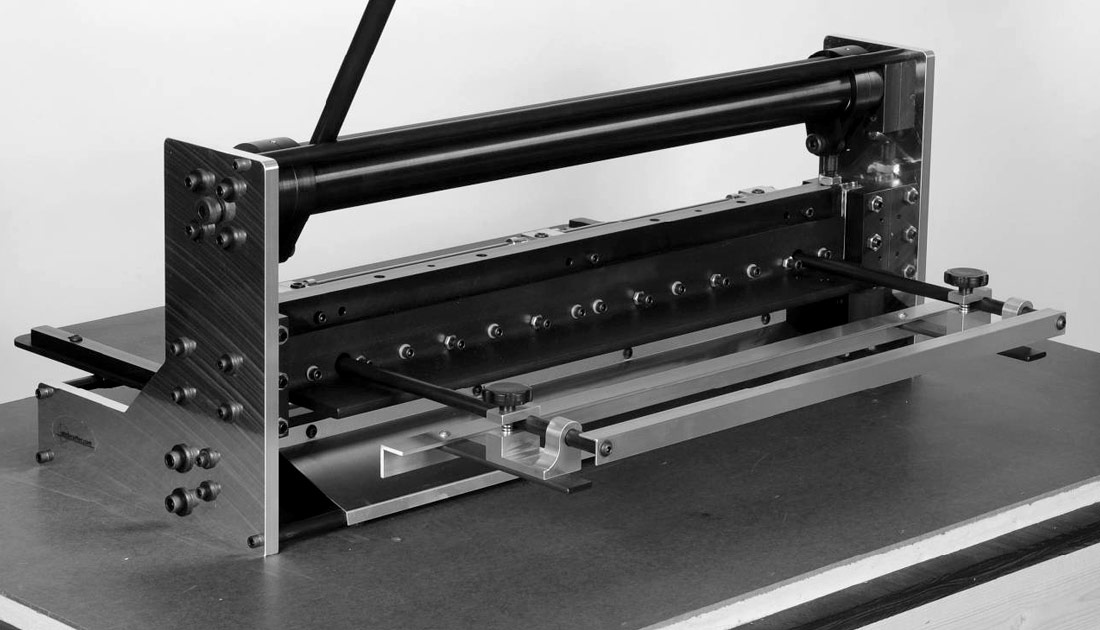

Accucutter Finishing Shear – Cutting to Size

After the sheets are processed in the OrbX, they will need to be cut to size. The Accucutter shear will cut up to ⅛” thick Novacryl (PT-020, PT-040, PT-060, PT-080, PT-118). Novacryl has a PETG base that can be shear cut to a finished edge. Anything over an ⅛” will need to be routed or cut another way. The Accucutter has a sharp, angled guillotine blade that cuts cleanly through the PETG leaving a finished edge.

After the sheets are processed in the OrbX, they will need to be cut to size. The Accucutter shear will cut up to ⅛” thick Novacryl (PT-020, PT-040, PT-060, PT-080, PT-118). Novacryl has a PETG base that can be shear cut to a finished edge. Anything over an ⅛” will need to be routed or cut another way. The Accucutter has a sharp, angled guillotine blade that cuts cleanly through the PETG leaving a finished edge.

>> Learn more about routing and laser cutting photopolymer here..

The majority of ADA signs are ⅛” thick and can be shear cut. Typical the shear is placed in the photopolymer processing so that the OrbX operator can also use the shear. This process reduced the amount of time and labor associated with making the signs.

>> Learn More About the AccuCutter Finishing Shear

Kobo TC-851 Hot Stamp Machine – Applying Color

Once the signs are processed and cut to size the next step is to decorate with color. The majority of the photopolymer material used is the Novacryl PT Series. The PT Series has a clear PETG base and can be decorated with:

Once the signs are processed and cut to size the next step is to decorate with color. The majority of the photopolymer material used is the Novacryl PT Series. The PT Series has a clear PETG base and can be decorated with:

- first surface paint

- second surface paint

- second surface graphic

- UV digital print

- Second surface vinyl

- Or left clear to be used and an insert

After the color or graphic is applied, the raised letters and characters need to be decorated or tipped. The Kobo Hot Stamp Machine is a heat stamping press that applies colored foil to the tops of the letters and characters.

The foil colors available are limited. We generally see people tip white, black or grey. Custom PMS colors will need to be screen tipped.

>> Learn More About the Kobo Hot Stamp Machine

Getting Started – The ROI Bringing Photopolymer Production

The complete cost to bring photopolymer processing in-house is less than $45,000 USD including training. All the equipment ships from our warehouse in Bryan, OH and typically goes out with 1-3 business day from receipt of order.

The average shop can produce and ship 250-400 signs on a daily basis (contact us for a detailed breakdown). If your retail price for a finished sign for is approximately $1.00/square inch, your ROI is about 1,500 signs – a conservative number.

Profitability, quality and control are the driving forces behind purchasing equipment. If you sell over 1,000 ADA signs annually your company can realize many benefits from producing ADA signs in-house.

Request A FREE Quote or Sample Box

Please fill out the form below to get a FREE quote on our Photopolymer Processing Equipment package.