Boyd Sign Systems Awarded NovAcryl® Preferred Fabricator Status for ADA Signage

//

Comment0

Boyd Sign Systems, a leading manufacturer of ADA-compliant architectural illuminated and non-illuminated sign systems, has joined the elite ranks as Nova Polymers Preferred Fabricators of Novacryl®, the world’s most expansive line of high-quality photopolymer ADA signage.

Specifying Novacryl Photopolymer – An Animated Guide

ADA + Design = Novacryl® We recently created a fun, animated video that shows the process and the benefits of specifying our Novacryl® Design Series photopolymer for room identification signs. The Novacryl® Designer Series includes 6 products types that meet... Read More →

Why You Need To Change Your Bulbs

Improve Cycle Times and Quality Exposure to UV light is what creates the photopolymer elements of a sign. The photopolymer that comes in contact with the UV light hardens allowing the unexposed polymer to wash away in plain water during... Read More →

How To Improve Your Photopolymer Quality and Cycle Times

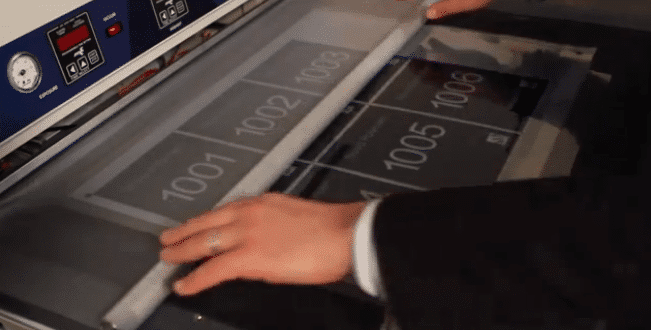

Better Vacuum Equals Better Quality As part of our Did You Know summer camapign, we thought it would be beneficial to talk about the importance of the vacuum processes when producing photopolymer signs. The vinyl cover sheet or “krene” is... Read More →

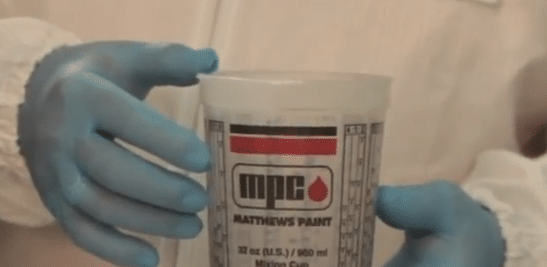

How To Apply Matthews LVOC Paint

Techniques for Painting Photopolymer Sheets The way you paint a photopolymer sign affects the tipping processing with hot stamp foil. The standard Matthews Acrylic Polyurethane (MAP) paint is applied and dries differently than the Matthews LVOC paint as they are... Read More →

Learn How To Paint NovAcryl Sign Material

NovAcryl and Matthew Paint Video Now Available In early October we went to a Matthews Paint training facility in California to shoot a training video that will walk you through the entire possess of painting NovAcryl photopolymer. While the video... Read More →

NovAcryl and Matthews Paint Video Shoot

NovAcryl Photopolymer Training Video Shoot Last week we made a trip to a Matthews Paint Training Facility in Rancho Cucamonga, CA to shoot a training video on how to paint NovAcryl photopolymer. We worked with Tim Llyod, Ronnie Waddell and... Read More →

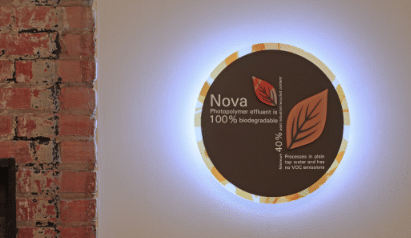

Creativity and Photopolymer Signs

Thinking Outside The Box Photopolymer signs are primarily used to identify rooms or spaces and typically include Braille. NovAcryl Series photopolymer offers a wide variety of design options that allow signage to match and/or compliment a facilities design. The question... Read More →

How To Laser Cut NovAcryl

Learn How To Laser Cut NovAcryl Laser Cut NovAcryl – The base material used for the NovAcryl PT Series Photopolymer is PETG (Polyethylene Terephthalate Glycol). Many people think that the clear base is acrylic and are often times surprised when... Read More →

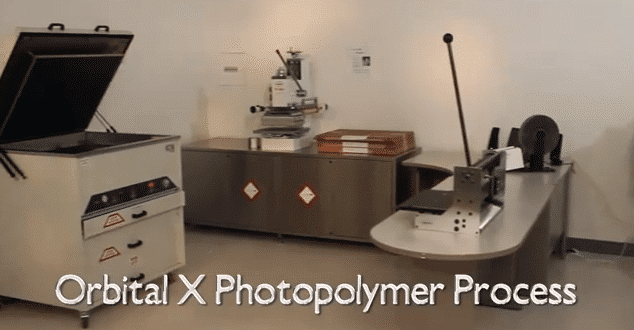

Learn How To Process Novacryl Photopolymer Signage

Novacryl Photopolymer Signs Processing Novacryl photopolymer signage is not as complicated or magical as some of you may think. There are several key pieces to make the process work and bringing photopolymer production in-house is not for every shop.