In this section, you will find information and videos for setting up a photopolymer production process. To get started you will need to generate files with Braille using our Workflow Manager Software, generate a film negative using our InkStar Film Solution, set up a Photopolymer Processing area which includes the Orbital X Photopolymer Processor, cutting area and tipping area.

Photopolymer Manufacturing Process

Processing Information

Set Up Requirements

WorkFlow Manager Software

Workflow Manager runs on a PC based computer. If you are using an Apple computer you will need to also have the Windows Operating System installed using Parallels or another similar software.

View the Workflow Manager Page for more Technical information.

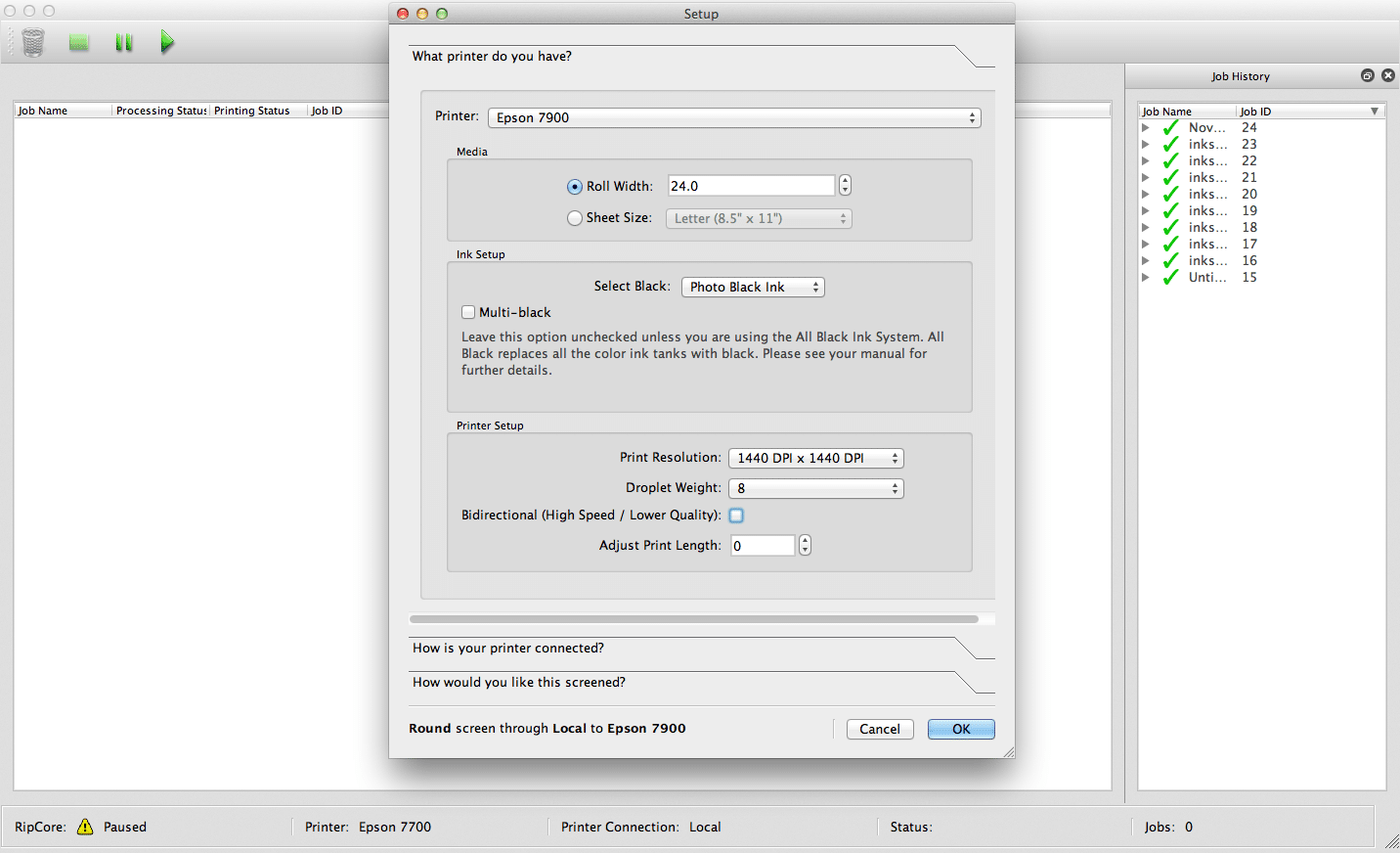

InkStar Printer and RIP Set Up

The InkStar Solution works with the Epson SureColor T3270 Printer and the AccuRIP software to produce high-quality film negatives and positives that meet the required density to exposure photopolymer.

Getting Started

- Select Photo Paper, Gloss 250 when installing a printer.

- Install AccuuRIP software on a PC or Mac computer.

- Click FILE then EDIT CONFIGURATION in the AccuRIP software.

- Set print resolution to 720 x 1440

- Set droplet weight to 10 (This may change but is a good starting point)

- Check the MULTI BLACK tab and un-check all inks but the Photo Black

- Insert the DyStar Photo Black ink cartridge into the Photo Black slot on the printer.

- Install the Dye Star Clear inks in all other slots making sure the correct labeled clear ink cartridge is in the correct slot.

- Click FILE then TEST PRINT. The results of this will be checked to determine the droplet weight setting. (Typically, between 9 and 12)

- Turn off the Auto Clean setting in the control menu on the printer.

- Always keep the printer turned on.

- Use a surge protector to power the computer.

- Always keep an extra Maintenance Tank on hand.

- Ink should be ordered when the current cartridge is around 50% capacity.

Orbital X

The Orbital X Photopolymer Processor is 220v Single Phase and requires a water line and a drain. The washout tank has a heating element that will maintain a temperature of 80 degrees Fahrenheit. A heated water line is recommended so that the water coming into the machine is up to temperature and ready for processing as soon as the tank is filled with water.

When the photopolymer comes out of the washout tank it will be wet. We recommend that you have a compressed air hose nearby to remove the standing moisture off the surface of the photopolymer before placing it in the drawer. This will reduce the amount of watermarks that are left on the surface of the photopolymer during the drying process.

View the Orbital X Photopolymer Page for more Technical information.

Kobo TC-851 Hot Stamp Device

The Kobo TC-851 Hot Stamp device is 220v Single Phase and weighs approx. 450lbs. The unit requires a strong, sturdy table. You will want to store the foil in a climate-controlled area so that the foil does not absorb moisture which will negatively affect the way the color transfers on to the photopolymer.

View the Kobo TC-851 Hot Stamping Page for more Technical information.

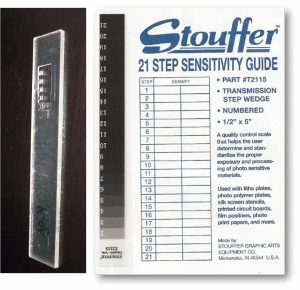

Stouffer Scale

The 21 Step Stouffer Scales is used to measure the amount of UV light needed to properly expose NovAcryl Photopolymer. As the bulbs age, they output less light which means that the exposure time increases. The Stouffer allows you to keep track of the UV output to ensure you are always exposing the photopolymer long enough.

The 21 Step Stouffer Scales is used to measure the amount of UV light needed to properly expose NovAcryl Photopolymer. As the bulbs age, they output less light which means that the exposure time increases. The Stouffer allows you to keep track of the UV output to ensure you are always exposing the photopolymer long enough.

Watch our Stouffer Scale video to learn more.

Epson Inkjet Printer Installation and SetUp