Pioneering Polymer

Innovation

Nova Polymers streamlines ADA compliance for architects and fabricators, offering comprehensive, high-value solutions.

Our top-tier support, training, and long-lasting photopolymer signs make us the industry leader in ADA compliant signage.

Featured Substrates

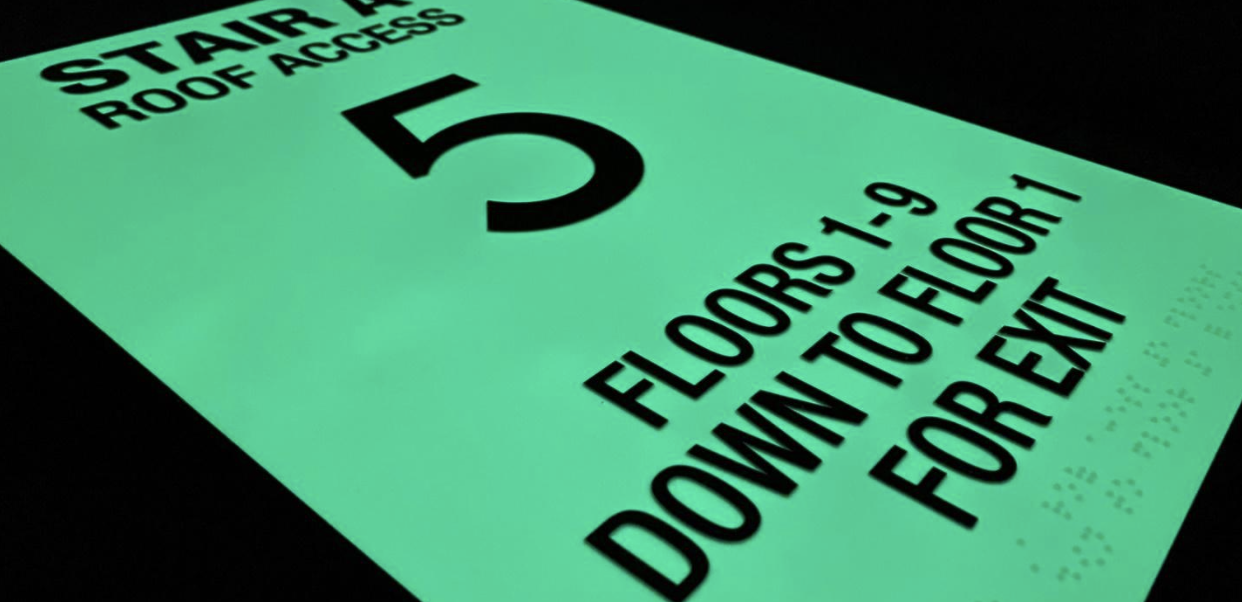

Novacryl® Permaglow 250TM

When seconds count in a building emergency, provide your customers with the optimum solution for safety and egress signage using

Novacryl® EX™ Series

Novacryl® EX™ Series is the industry’s first pure exterior-grade photopolymer, designed for durability in high-moisture and high-humidity environments. This versatile

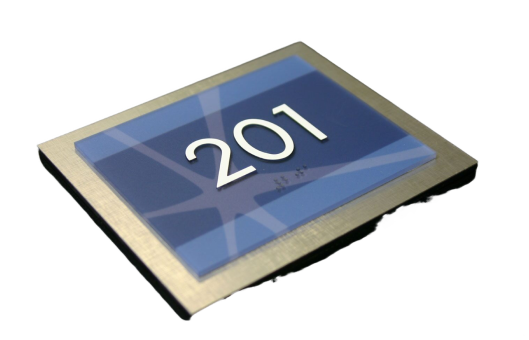

Novacryl® AC™ Series

Novacryl® AC™ Series is an acrylic photopolymer substrate designed to reduce your production costs while providing various options for creating

Novacryl PT Series Clear PETG

The greenest and most versatile line of signage photopolymer. The most versatile line of signage photopolymer. With the Novacryl® PT™

Novacryl® PG™ Series

The ideal solution for safety and egress signage needs. The solution for safety and egress signage concerns: Light the way

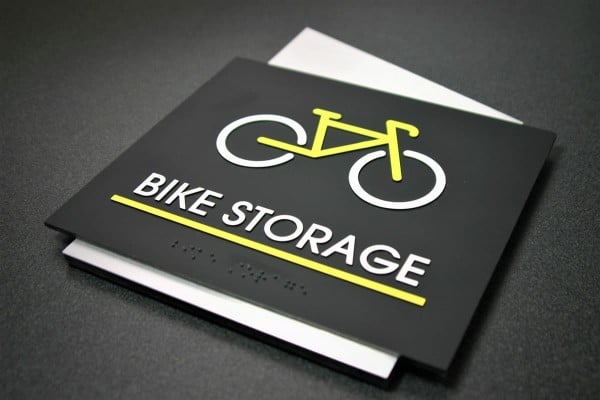

Novacryl® LP™ Series

Choose from a range of materials, colors, and patterns. Customizable signage for designers and fabricators: With the Novacryl® LP™ Series,

Novacryl® PT™ Series BLACK PETG

No painting is required and it ships 2-3 days quicker. Ship signs 2-3 days quicker! With high-end opaque color and

Novacryl® PT™ Series WHITE PETG

Requires no painting, saving on fabrication lead time. No painting required! Save on sign fabrication lead time and be ready

Novacryl® BR Series

Moisture-resistant aluminum-backed photopolymer. Our brushed aluminum-backed photopolymer. The Novacryl® BR Series consists of the same interior-grade material as our PT

First and Only Creator of Clear

Photopolymer

We’ve set the standard for innovation in accessible signage by creating the first clear photopolymer that is made to last.

Choose the permanence of photopolymer signage. Unlike other ADA sign fabrication processes, our durable and long-lasting solutions withstand constant tactile contact, ensuring braille signs remain reliable. Trust in quality that endures for a truly inclusive and accessible environment for all.

Innovation Means

Inclusivity

ADA-Braille 100% compliant signage is not just our business—it’s our mission. We are proud to offer ADA sign training and support.

Architects

ADA Signage Solutions

Our diverse range of photopolymer raw materials and technology allows for the design and fabrication of ADA braille and accessible room identification signage, including several products that help achieve USGBC/LEED certification.

Nova Polymers is your single source for innovative, environmentally conscious photopolymer signage equipment, material, and software solutions. Create branding through our materials and unlock the potential to make a lasting impact for all. And, when you need to brush up on training, Nova offers a free ADA (Sign specifications) webinar series for architects.

Fabricators

Streamline Your Process

With financing options available,Investing in polymer ADA Braille sign production is a secure, materials-efficient choice for your business. Our design software minimizes the risk of human error and material waste. Improve your production capabilities and secure long-term support.

Nova Polymers is your single source for innovative, environmentally conscious photopolymer signage equipment, material, and software solutions. Create branding through our materials and unlock the potential to make a lasting impact for all. And, when you need to brush up on training, Nova offers a free ADA (Sign specifications) webinar series for architects.

NOVA Polymers'

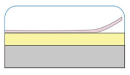

5 Step Process

Processing Novacryl® photopolymer signs is easy and straightforward, resulting in high-quality ADA compliant braille and accessibility room identification signage.

At Nova, we make this process easy to follow and understand. There are five simple steps, and we provide all the resources necessary to process correctly and ensure ADA compliance.

Our Novacryl Processing Guidelines will walk you through the details associated with actual processing time and procedures.

Step 1

Contact With Film Negative

Place a high-density film negative on top of the photopolymer sheet.

Step 2

Exposure with UV Light

There is a bank of UV lamps that shine down and pass through the clear areas of the film negative and expose the photopolymer material.

Step 3

Wash in Plain Tap Water

The unexposed photopolymer gets washed away during the washout process in plain tap water. The photopolymer effluent is 100% biodegradable and goes right down the drain. You are left with the exposed raised images.

Step 4

Drying

Dry the moisture off the material. The photopolymer and the base PETG do not absorb moisture during the washout – drying is to evaporate any standing moisture left on the sheet.

Step 5

Post Exposure

Post exposure is a second exposure to fully cure, harden, and activate the photopolymer. This is the final step in processing the photopolymer.

Color Pro Ink Tipping

Machine

The Nova Polymers’ Color Pro is a game-changing solution for sign makers who want to increase their ink tipping processing and speed.