4 Ways you can Tighten Your Specifications to Ensure Project Success

Has every architect or designer heard this discussion before?

Architect: I am receiving complaints from my client, the building developer. She tells me that the signs we installed a few months ago are failing. People handling the signs are causing them to discolor and pieces are falling off.

Fabricator: OK. That is a tough situation.

Architect: We thought about this in advance and specified heavier duty materials. Were they used in the project?

Fabricator: Well remember we said we found a similar alternative that cut the cost by 5%.

Architect: How similar is it! It’s failing. I never asked you to change this specification. We clearly set we wanted more durable materials. You are going to have to replace them.

Fabricator: Well it is a gray area.

This conversation is a common issue between architects and fabricators. Architects have it in their best interest to buy the best materials for a given context even if it costs a little more. The price to the architect is much more if the material fails than the small price savings to the client. This often results in contentious arguments with the client to balance price and quality.

Fabricators can have the opposite incentives. They have a better chance of getting the work in a bid by using less expensive but less durable materials which is not always evident when the project is first built. They are not exposed to all the meetings with the client where these issues are hashed out. Many times they have the best intentions thinking that the alternatives are good enough for the context, but on the other side do not feel responsible for the failure since they noted the alternative in their bid.

So what is an architect or designer to do? There is no easy solution, but the best approach is to lock down the most important specifications before the bid process. These approaches particularly help strong fabricators who architects should want to encourage to succeed. These fabricators are reluctant to sacrifice quality for price.

This involves four elements:

1. Tighten the specification

While performance specifications play a great role when there is an open negotiation of materials between fabricator, designer and client there is an enormous chance of breakdown during a bidding process when fabricators are looking for any opportunity to cut costs. Tightened specifications for bidding including specific materials and methodologies should keep bids in line.

While performance specifications play a great role when there is an open negotiation of materials between fabricator, designer and client there is an enormous chance of breakdown during a bidding process when fabricators are looking for any opportunity to cut costs. Tightened specifications for bidding including specific materials and methodologies should keep bids in line.

This interior sign fabricated by Nieman & Company used Novacryl ECR with 3Form Fossil Leaf Random pattern backpainted in wisteria and top coated in cream. For this sign to be successfully carried out the full specifications needed to include clear product descriptions for coatings, polymer, and substrate.

2. Provide reasons for qualification

When developing a specification, even a technical specification, put in the specific reasons why that specification was utilized. This further reinforces the issues behind the choice, and requires the fabricator to clearly put through any changes.

3. Have an open informational meeting during the bid process

Before final bid submittal have an informational meeting to review the key elements of the specification. This allows the opportunity to ask specific questions about changes. Strong fabricators will use this opportunity to discuss changes in detail. For negotiated bids a formal meeting between designer, client and fabricator would produce even greater assurance on specification changes.

4. Assuring the Change

If the fabricator wants to make a change on a bid require an explanation of the change and provide

If the fabricator wants to make a change on a bid require an explanation of the change and provide

a one year warranty if the specification is based on durability. One year is enough time to assure

performance of the material change. Another approach is to have a second performance punch list

three months after installation. This assures that any immediate problems are addressed.

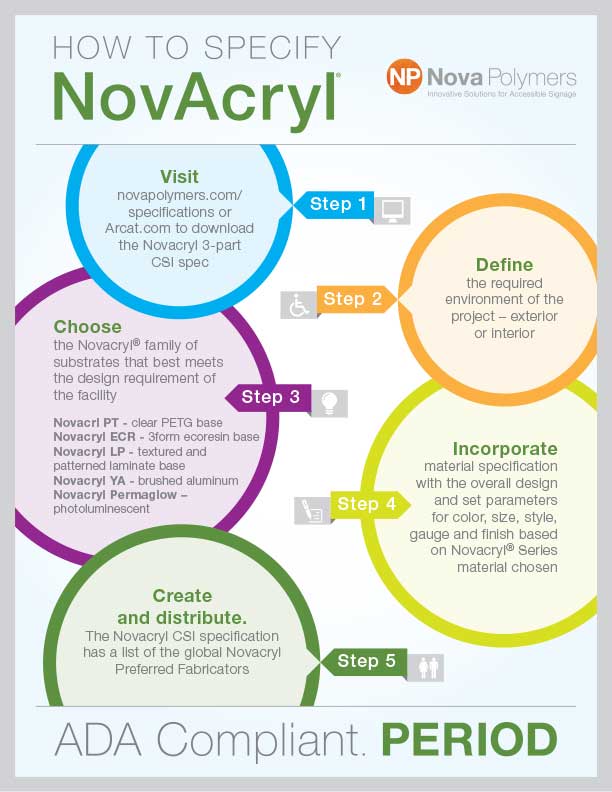

Nova Polymers provides a document on specifying NovaAcryl that any architect or designer can easily follow and integrate into their documentation set. Go to novapolymers.com/how-to-specify-novacryl to download the entire document.